Low PSI (Swisspacer) Processing

Equipped for modern low psi profiles

Modern technology for modern technology

The crowning glory of our product division: ultrasonic welding technology for the industrial processing of modern Low Psi (Swisspacer) profiles into spacer frames.

Play Video

Leaflet Low Psi-Profiles_german

Leaflet Low Psi-Profiles_eng

With our proven Roweldo-Romillo combination, one person achieves cycle times of less than 30 seconds. Suitable for processing all common low psi profiles such as Swisspacer, Multitec or comparable products.

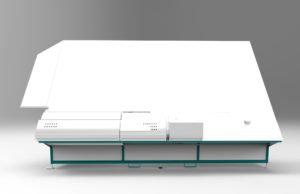

Roweldo XL - the 4-head welding system

- Individually inserted frame parts are automatically joined and welded

- Automatic welding of all four corners in one operation

- Clean corners, therfore a proper butyl surface and minimal thickening

- Interior view is identical to inserted corners without any deformities

- High frame and dimensional stability

- Automatic positioning of the welding head through online connectivity

- Cycle times of less than 30 seconds

Romillo XL - the cutting machine

- Frame parts are milled to 45°

- Automatic insertion of the corner brackets

- Longitudinal welding of the profiles for endless connection

- Compatible with 25-compartments magazine PWM 20 XL

- Cycle times of less than 30 seconds

- Minimal waste due to optimum residual length management

For smaller quantities we recommend the combination of Roweldo S and Bendit with Low Psi option.

Roweldo S - the 4-head welding system

- Automatic welding of the corners one after the other

- Manual positioning for the welding process

- Clean corners, therfore a proper butyl surface and minimal thickening

- Interior view is identical to inserted corners without any deformities

- High frame and dimensional stability

- Automatic positioning of the welding head through online connectivity

- Cycle times of less than 50 seconds

Bendit with Low Psi Option

- Integration of Swisspacer / Multitec processing

- Individual magazine configurations between 10 and 25 compartments

- Universal bending tools for almost all hybrid profiles

- Tight corner radii

- Rolling technique to support plastic deformation

- Counter support bending with profile-specific tools for almost any profile

- Modular machine design for perfect customisation

- Large one-piece frames

- Integrated radius bending

Subject to technical changes

© 2022, Rottler und Rüdiger und Partner GmbH. All rights reserved.